Rajkot Machine Tools Show is the leading exhibition in the machine tools hub of western India. It serves as a one-stop destination for the machine tools, automotive & ancillaries manufacturing industry. The exhibition addresses the industry’s requirements, provides leverage and enhances their manufacturing capabilities with the latest technologies, tools and solutions. It has, over time, enabled large industries and other small and medium enterprises (SMEs) to generate revenue with worldwide networking. The expo covers the entire gamut of machine tools, ancillary industries and other engineering technologies essential for tomorrow’s manufacturing.

RMTS 2022 or Rajkot Machine Tools Show presents an exclusive display of machine tools, automation, and automotive technology. Renowned for meeting the needs of its clientele, it has accumulated 60 reviews. It has only aimed at a strong client base with each edition. Through its products and services, the exhibition aims to create a satisfying experience.

RMTS proves to be the ultimate facilitator for B2B cooperation in the industrialized state of Gujarat. It stands as a strong bridge between manufacturers and customers of all hues connected to the machine tools industry. The participating companies generate targeted sales leads and future business development, demonstrate their products to appropriate audiences, network with their key customers and upgrade their knowledge of new technologies & concepts in the market. It stands to be India’s Premier exhibition of metal cutting, metal forming, automation, forging & Foundry.

With unlimited possibilities for growth, the previous edition of the Rajkot Machine Tools Show was executed beyond expectations. The 3-day exhibition was in action at NSIC Ground in the Aji Industrial Area of Rajkot, Gujarat. Its interactive networking experience extended to all visitors and participants, infrastructure and state-of-the-art amenities of its venue. Rajkot Machine Tools Show 2022, organized by K and D Communication Limited, is a one-stop destination for the best B2B collaboration facilitator for manufacturers and clients of all stripes associated with the machine tools sector in India.

Expanding their understanding of emerging technologies & market concepts, the exhibitor category is inclusive of Machine tools-cutting & Forming, Power Tools & Hand Tools, Robotics & Automation, Brass Parts, ITES (Software, CAD-CAM), and Air Compressor, Testing & Measuring Instruments, Tube & Pine Technology, Newly Launched Products & Technology and others.

Over time, K and D Communication Limited have broken all the traditional expectations by becoming India’s leading exhibitor for the engineering sector that brings together players from all of the related fields registered for humongous sales and interactive and fruitful deals. Emerging innovations, knowledge exchange with world leaders, investment opportunities and business tie-ups are the highlights of their event.

Cosmos Impex is India’s leading machine tools manufacturer of both Indian and imported products. With over 35 years of experience in the Machine Tools Industry in India, the Group holds over 20 years of manufacturing experience. They also have recently started the construction of Phase-I of their state-of-the-art technology park. This park is located at Ranu village in the Vadodara district of Gujarat. They target the entire project to complete in three phases and be operational by 2022.

The company plans on hiring a large number of engineers & technicians for this tech park. Professionals will be, however, hired in a phased manner. The technology park will have various plants producing key components to manufacture CNC Machine Tools. It will also comprise the R&D Division that will be a growth driver to their future business. COSMOS has already built technology alliances with some of the top machine tool industry leaders in the world. Uniquely, with this ambitious venture, COSMOS is playing their trump card for the growth of Indian industry in the fields of the Automobile, Infrastructure, Power & Steel, Electronics, and Aerospace & Medical Implants.

The company is investing close to ₹100 Cr in setting up of this technology park that covers 15 acres of land area. COSMOS is dedicated to their efforts for social and environmental issues. They hope to enrich the quality of life of the community they serve. To support that, the tech-park will take a lead in green initiatives. It will be surrounded by greenery all over the campus. They also plan on creating a rain forest facility. COSMOS tech-park aims at improving the synergy among its various divisions while bringing the majority of its operations to a single campus.

The technology parks will enable interaction of their group companies to work in harmony to evolve new technologies starting from inventions.

Mr. Nagesh Velaga (Director, COSMOS)

The cosmopolitan city of Vadodara is also the engineering capital of Gujarat. Gujarat has served the best soil to root businesses. A lot of employment generation will take place too due to setting up of this tech park. It would be the hub of several key businesses of the COSMOS group. In the light of sustainability, the 15 acres Tech-Park will offer single-point design, engineering and development solutions to the core sector industry.

Not to mention, this Technology Park will enable COSMOS Group to have all manufacturing process under one roof. It will serve the best control of systems with quality and delivery as per their customer needs. Long term ventures & associations with International Machine tool companies and over 800 employees are significant milestones in the growth story of the Group.

Read more about COSMOS and other exhibitors of the upcoming edition of ENGIMACH 2021 in our newsletter.

Gujarat’s manufacturing industry is set to take the center stage, as it is one of the leading industrialized states in India with a GSDP of ₹16.59 trillion. The state’s GSDP increased at a CAGR of 10.02 per cent between 2015-2016 and 2020-21. It could grow further by 4-folds to ₹40 lakh CR by 2030. It is the top recipient of FDI among states, with a 37 per cent share of total FDI equity inflows. The sectors of computer software & hardware and construction & infrastructure-related activities are the major contributors during FY21. Maharashtra and Karnataka with 27 per cent and 13 per cent respectively follows.

The Government of India announced the Production-Linked Incentive (PLI) scheme in March. It outlays ₹40,000 Cr for the benefit of 10 different sectors, including electronics and technology. While they continue to come up with various measures, they’ve supported the infrastructure sector by inviting investments from the sovereign wealth funds, interests to which will be tax-exempt.

The recent budget focuses on capacity improvement to spend for the rural sector, infrastructure creation, and investment invitations. In a seminar titled Gujarat’s sprint to 2022, Gujarat Chief Minister Vijay Rupani mentioned the Gujarat manufacturing industry alone will be contributing a staggering 30 per cent to the state GSDP by 2030. Undoubtedly, the state has been a power surplus. With the help of desalination plants and the best water management technology, he added, Gujarat could soon become a drinking water surplus state.

Gujarat serves the best soil to root business ideas. Momentously, the government is initiating measures to improve infrastructure, regulations, and job opportunities. It is finally ready to help the country step up for global domination. Import substitution, reviving demands and promoting export-oriented industrialization drives the Indian economy. The government has also declared incentives for niche electronics manufacturers. As a result, they’re now eligible for a payment of 4-6% of their incremental sales over the next five years.

ENGIMACH 2021 – organized, managed and marketed by K and D Communication Limited, is determined to be one of the prime contributors to the development of the machine tools industry. It enables its participants and visitors with cutting-edge and powerhouse technology that stands for engineering excellence, innovation, quality, and reliability.

The showcase at ENGIMACH has offered a quintessential launchpad for new ideas, products and services. With a conducive environment for forging joint ventures and collaborations, it lays out an open marketplace to source ideal solutions. Over 1,00,000 business visitors and beneficiaries in the Engineering & Machine Tools Industry have been a part of the trade show.

With the market re-establishing itself, returning to how the world was pre-pandemic anytime soon is unlikely. Trade fairs, however, contribute to the bolt by compressing the entire platform of manufactures, suppliers, and potential buyers of individual economic sectors to one physical place laying out opportunities not only to make higher sales within a smaller period but also to grasp complete awareness of where your competitors are at. The government has listed managing health crises and reviving the economy as their top priority.

Generally speaking, trade fairs play a critical role in the instauration of the economy. They present a chance for companies to buy, sell, and source. Ordinarily, they became a vital component in the business calendar, a key factor in building networks and gauging competition. The Indian Exhibition Industry Association (IEIA) estimates the market size of the exhibition industry at ₹23,800 Cr. India entertained over 550 events annually before the pandemic hit.

With new safety protocols, exhibitions will be a controlled environment. The entire process is safe for a visitor. On balance, it allows contactless entry and meetings, cashless transactions, and social distancing; while being able to resume liquidity in the market is the restart our economy awaits.

In a word, ENGIMACH has proven to be a prodigious trade fair. It sets a platform for presenting and viewing the industry’s technological prowess and innovations. The worldwide networking, pre-emptive planning and execution, and diligent control of macro and micro-level logistics benefits the participants. These include businessmen, industry experts, Government officials, decision-makers, investors as well as visitors coming in from different segments of the engineering, manufacturing and technology sector.

We are focused on raising the standards of exhibitions through commitment, passion and extraordinary efforts. We strive to provide exceptional and innovative experiences in business promotions and networking. It served as a catalyst to their tremendous growth and development.

says Kamlesh Gohil, CMD, K and D Communication Limited

Through our committed endeavor and a no-compromise attitude, the exhibition ensures a payback from the event. It has made us to stand as Asia’s most dynamic engineering, machinery, material handling, and machine tools exhibition. The 14th edition of the trade show was one of the most comprehensive and protracted events. With world-class facilities for product display, corporate communications, publicity, promotions, liaison with government bodies, and inter and intra-business interaction, the upcoming edition is determined to be the prime contributor to the boost that our economy needs.

The FAME India project supports the hybrid and electric vehicle market, its development and manufacturing ecosystem. In the first place, they had launched the National Electric Mobility Mission Plan (NEMMP) 2020 to attain 6-7 million sales year on year from 2020 onward. The government aims to achieve national fuel security by promoting the same and provides fiscal and monetary incentives to kick start this nascent technology. This would not only benefit the electrical and manufacturing industry but also the auto component and green energy sector. These sectors are also the key focus sectors of ENGIMACH 2021 organized by K and D Communication Ltd.

The FAME scheme had an outlay of ₹8.95 billion and provided subsidies for electric vehicles. This included two-wheelers and three-wheelers, hybrids and e-cars and buses. Phase-I initially launched for 2 years, focused on implementation through demand creation, technology platform, pilot project and charging infrastructure.

To further promote sustainable growth, the year 2015 witnessed the launch of the Faster Adoption and Manufacturing of (Hybrid &) Electric Vehicles in India (FAME India) Scheme. Grants for specific projects were also sanctioned under these components. EVs under all vehicle segments could benefit from the demand incentive of ₹343 Cr approx. in the form of an upfront reduced purchase price. The National Automotive Board under D/o Heavy Industry implemented and monitored the amount of incentives availed. The government of India launched the scheme under National Mission on Electric Mobility in 2011/ National Electric Mobility Mission Plan 2020. As a result of this, there could be a raise progressive induction of reliable, affordable and effective electric vehicles.

Subsequently, the extension shifted from time to time. Lastly, the extension was allowed up to 31st March 2019 under the framework of the Demand Incentive Disbursement Mechanism. At present, the scheme has 30 Original Equipment Manufacturers registered under it with 137 models of all categories. The electrification expects about 50 million liters of fuel-saving and about 129 million kg CO2 reduction. The digitalized portal of the schemes shows the benefits of e-vehicles sold. Additionally, the portal reflects MIS reports to help in monitoring and management.

Commencing from April 2019, the Department of Heavy Industry approved Phase II of the scheme – FAME II with an outlay of ₹10,000 Cr for 3 years. It allotted about 85 per cent of the total budgetary support for demand incentives. The aim furthermore is to support an estimate of 7000 e-buses, 10 Lacs electric two-wheelers, 5 Lacs electric three-wheelers and 55000 electric four-wheeler passenger cars including strong hybrid.

The scheme encourages manufacturers to build electric vehicles while also creating and developing charging infrastructure. The government estimate spending of around 10,000 Cr on this phase in the upcoming year of 2021 and 2022. It states that there will be high use of electric buses to reduce pollution, traffic and other types of difficulties. The scheme mainly focuses on private vehicles in the two-wheeler segment in metropolitan cities. It encourages the use of electrical charging stations over diesel and petrol ones. The Government of India has planned on giving out 670 e-buses in the state of Chandigarh, Goa, Gujarat and Maharashtra and creating 241 charging stations. These stations, supposedly, are to be planted by the roads of Gujarat, Kerala, Madhya Pradesh, Port Blair and Tamil Nadu.

To be eligible for incentives under phase-II of the scheme, vehicles ought to meet minimum technical criteria and registered as “Motor Vehicles” as per CMVR. Although, only vehicles fitted with advanced chemical batteries fall under the criteria. The scheme will apply to vehicles used for public transportation, registered for commercial purposes in e-3W, e-4W and e-bus, or private-owned vehicles registered as e-2Ws to generate greater emphasis for the masses.

The government, however, has not yet prescribed any application procedure for the subsidiary under FAME-II. Check for update on the official website of heavy industry, ministry of heavy industries and public enterprises, Government of India.

The current Gross Value Added (GVA) from the manufacturing sector was estimated at US$350.27 billion by the end of the financial year 2021. On balance, it accounts for 19% of the country’s Gross Value Added. A recent survey estimates the capacity utilization in the manufacturing industry to stand at 63% in the second quarter of FY21.

IHS Markit complied Manufacturing Purchasing Managers Index (PMI) increased by 1.3 from December 2020 to January 2021. According to the Ministry of Statistics & Programme Implementation, the country’s industrial output reached 135.2 in December 2021, while the industrial output indices for the manufacturing sector alone stood at 135. in January 2021.

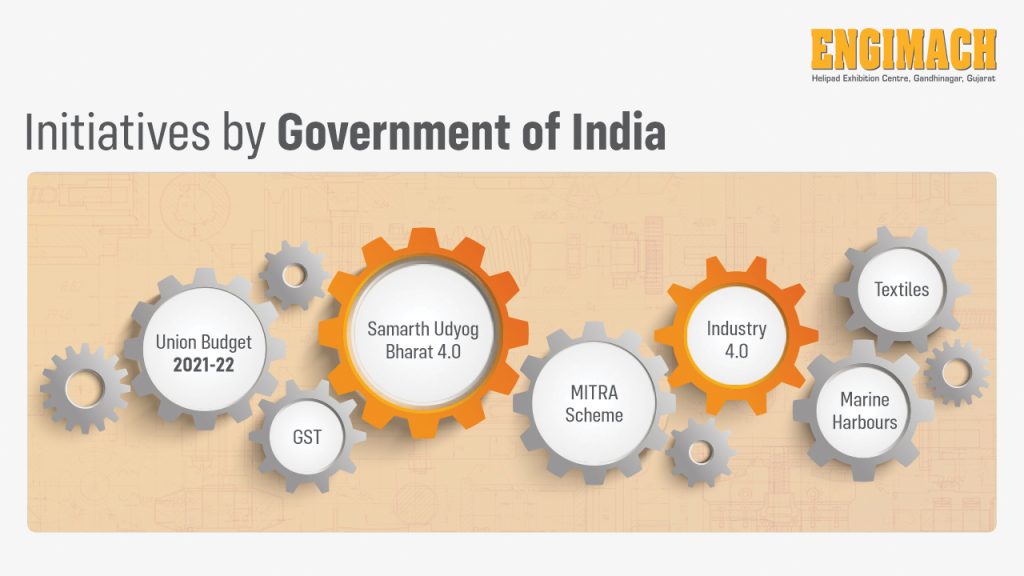

Industry 4.0 aims at automation and data exchange in the current manufacturing technologies, including cyber-physical systems, the Internet of things (IoT), cloud computing and cognitive computing and creating the smart factory.

The government of India set up a 22 member Inter-ministerial Committee in November 2020. It presented the idea of strengthening the Capital Goods sector, enabling its contribution towards the goal of achieving the US $5 trillion economy. The data includes the US $1 from the manufacturing sector. Up to the present time, they have already set a target of increasing the contribution of manufacturing output to 25% of our GDP by 2025.

This committee’s agenda includes technology development, global value chains and skill development as per the global standards. They are working on improving custom duties procedures to make the sector stronger on international platforms. Given these points, India could become the manufacturing hub of the world. In January 2021, the 6th inter-ministerial Review Committee for Capital Goods scheme gathered to plan the creation of an eco-system for R&D for manufacturing technology. The development of based open manufacturing technology innovation platforms is the step towards it.

It is known that an increasing number of industries and professionals are beginning skill enchantment programmes. It is not only for immediate implementation but also to make the employees ready for the future. Industry 4.0 Digitization is becoming popular with time. However, a hitch in the mindset of the industry personnel still exists for participating in the automation projects and training.

The approach seems to be the way ahead even in the MSMEs. Senior level managers would be required to take this initiative forward so India could paint the globe with its vibrant manufacturing economy. K & D Communication Ltd puts forwards ENGIMACH 2021 as our share of contribution in the learning process. ENGIMACH is a platform for the Indian engineering and manufacturing industry to come out and address the innovation, trend and scope of the industry.